The math behind the millimetres: Unmasking the mysteries of decking discrepancies

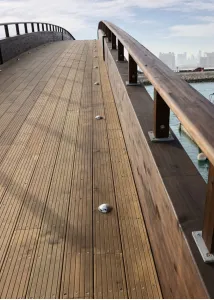

The precision of board dimensions: every millimetre matters!

In the intricate world of woodworking, even the tiniest detail holds immense importance. A simple deviation, as minor as a few millimetres, can often be the difference between a project's success and failure. This isn’t just a mere statement, but a testament to the detailed craftsmanship required in the domain of woodworking.

The power of a millimetre in woodworking.

While many online influencers and bloggers highlight minor discrepancies, they sometimes overlook the broader implications of these deviations. Consequently, their audience might develop misconceptions about woodworking's nuances. These inaccuracies not only stir unwarranted debates but can also lead to grave practical errors.

The costly consequences of dimensional mistakes.

Dimensional inaccuracies are more than just a pinch on your wallet. They can result in wasted hours, frayed nerves, and, more damagingly, a tarnished rapport with clients. The act of selecting the perfect board transcends mere resource conservation - it’s a cornerstone for fostering a fruitful collaboration. Thus, it's crucial to sidestep flashy marketing tactics and instead delve into the insights offered by woodworking maestros.

A closer look at woodworking specifications.

To assist you in making well-informed choices, our aim is to furnish you with precise and technically sound information. Viewing woodworking through a scientific lens reveals a myriad of factors influencing the end product's attributes. Foremost among these is the crucial element of timber dimensions. In today's discourse, we focus on dry planed profiled boards—a category encompassing a vast array of products from decking boards to cladding.

Decoding the subtleties of decking.

Using decking as our focal point, it's essential to understand that the principles we discuss aren't exclusive to this category but are broadly applicable across woodworking products. Dive deep into this realm, and you'll find the market flooded with a plethora of planed lumber types, each with its own set of standards and regulations.

The role of standard sizes in woodworking companies.

A noteworthy point is that woodworking companies often establish and adhere to their unique set of standard sizes. These decisions are moulded by various determinants such as the specific equipment in use, the adopted technological procedures, and the skillset and experience of the personnel.

Unveiling the technological nuances: every millimetre tells a tale.

Indeed, the variations in board sizes, no matter how minuscule, often reflect a company's bespoke technological approach. The dynamic realm of woodworking, unfortunately, has become riddled with marketing antics where hyperboles overshadow genuine advancements. Marketers often parade mundane enhancements as groundbreaking revelations, leading to distorted consumer perceptions.

Navigating the maze of woodworking marketing.

It's paramount to approach the woodworking industry with discerning eyes, immune to the lure of audacious marketing claims. While it's tantalizing to get swayed by flashy advertisements, reality often paints a different picture. An off-mark of mere millimetres can translate into operational challenges, something that consumers realize only when they grapple with the reality vs. expectation chasm. The outcome? A growing tribe of disillusioned customers rallying against these slight but significant discrepancies.

Deep diving into woodworking standards: spotlight on larch decking boards.

As we navigate the intricate standards of woodworking, our primary focus shall be the specific dimensions of larch decking boards. It's a realm where precision intertwines with functionality, and here we'll shed light on the benchmark set by industry leaders.

Deck board standard dimensions by Timber Expert

| Thickness, mm | Width, mm | Length, m |

| 28 | 90 | 2-6 |

| 28 | 120 | 2-6 |

| 28 | 140 | 2-6 |

| 35 | 90 | 2-6 |

| 35 | 120 | 2-6 |

| 35 | 140 | 2-6 |

| 45 | 90 | 2-6 |

| 45 | 120 | 2-6 |

| 45 | 140 | 2-6 |

The art of crafting non-standard board sizes.

Have you ever found yourself intrigued by the allure of wider boards, measuring 160mm, 180mm, or an impressive 200mm? If you've embarked on a quest to find such sizes in the market, you'd know that they're quite the rarity. And there's a cogent rationale behind their limited presence.

The intricacies of producing wide boards.

Crafting wider boards is not a mere extension of standard processes—it demands a unique blend of meticulous care and expertise. The journey commences at the drying phase, ensuring that these broad boards remain free from cracks. As they progress through subsequent processing stages, they call for heightened skills and a comprehensive understanding of the material's physics. Given their propensity to warp or twist, it's pivotal to strike a perfect balance between the board's thickness, width, and length. For an in-depth insight into how the dimensions of decking boards impact their longevity, one can delve into the article titled

"Crafting the perfect deck: an Insider's guide to choosing the right size decking."

Why wide boards are a production challenge.

These complexities render the fabrication of wide boards a herculean task. It's not an endeavour every woodworking enterprise is equipped or willing to undertake. Consequently, the market is predominantly populated with the more conventional 28x140 mm size, courtesy of its straightforward production process. So, if you're setting your sights on boards boasting widths of 180-200 mm, it's crucial to equip yourself with this knowledge. Be prepared for an in-depth consultation when placing such bespoke orders.

Navigating the Social Media Labyrinth: Decoding Decking Board Dimensions.

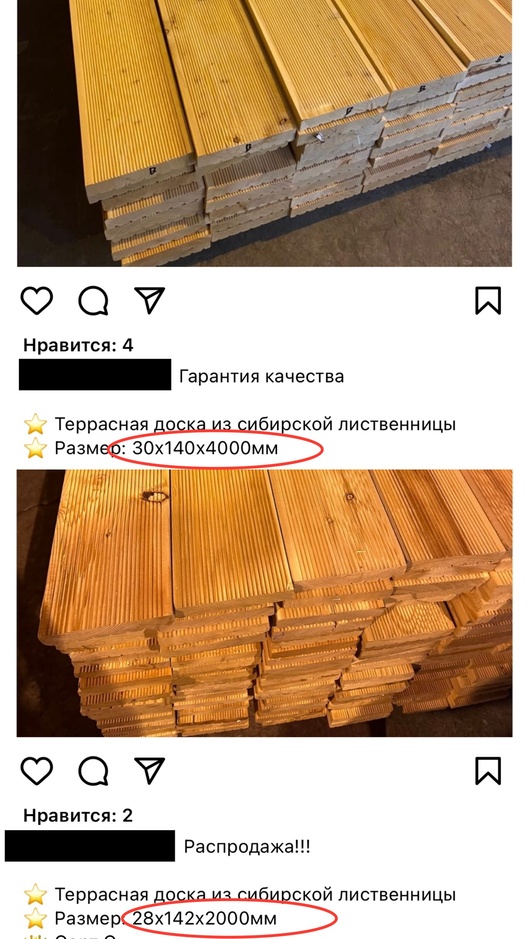

Welcome to the vibrant, ever-evolving landscape of social media—a universe where everyone claims expertise and information often metamorphoses with every share, resembling a digital game of 'Chinese whispers'. Let's embark on a voyage through this vast sea of data, aiming to unearth the authentic story behind the prevalent terrace board size of 28x140.

Navigating the digital labyrinth of dimensions

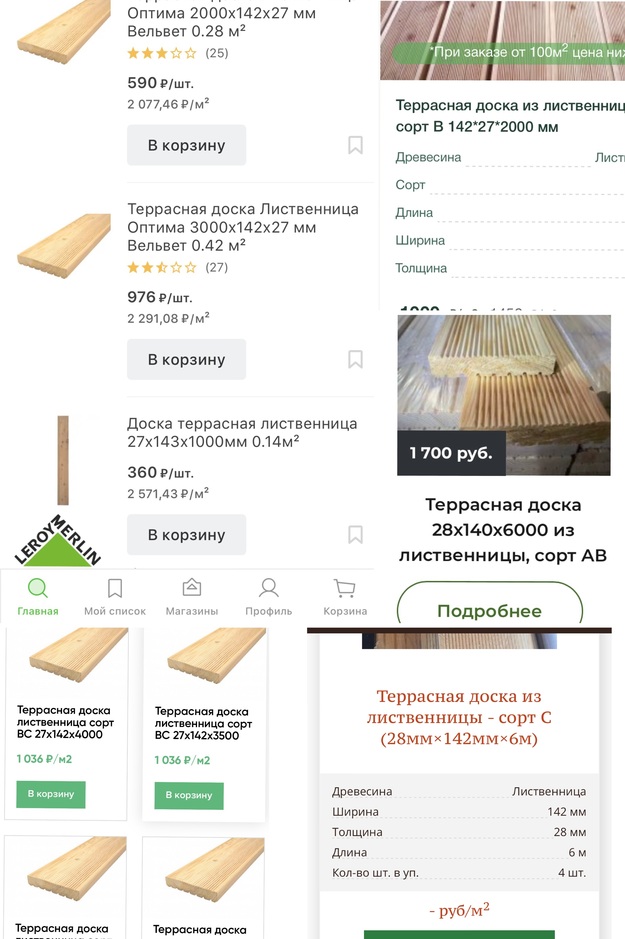

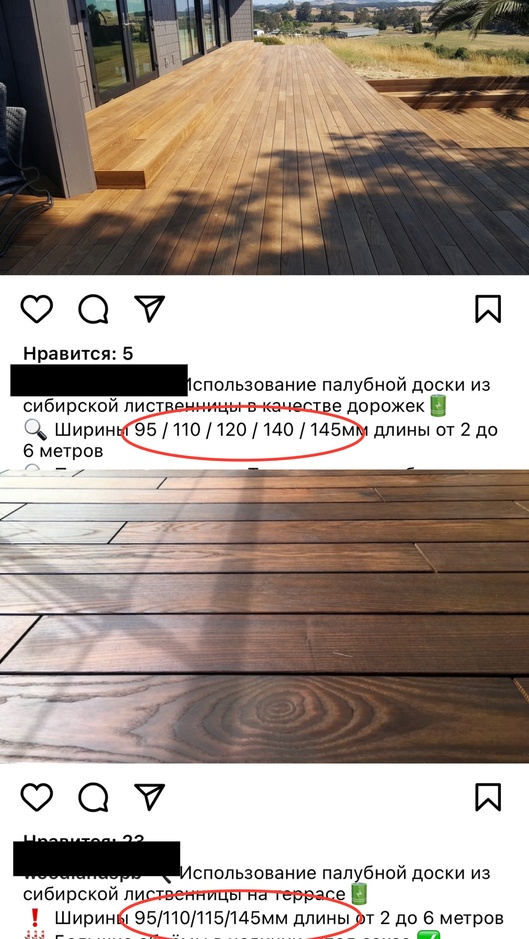

In this vast online realm, you'll encounter multiple versions of what's 'standard'. Some platforms tout 28x142, others 28x143, and some even venture into the realms of 28x145 and 30x140. It's a genuine maze! Consider, for instance, the decking boards from Leroy Merlin. They're listed in a plethora of sizes, such as 27x142 mm and 27x143 mm. Is this a reflection of Leroy Merlin sourcing from diverse manufacturers or simply a typographical oversight by an eager copywriter? The plot thickens!

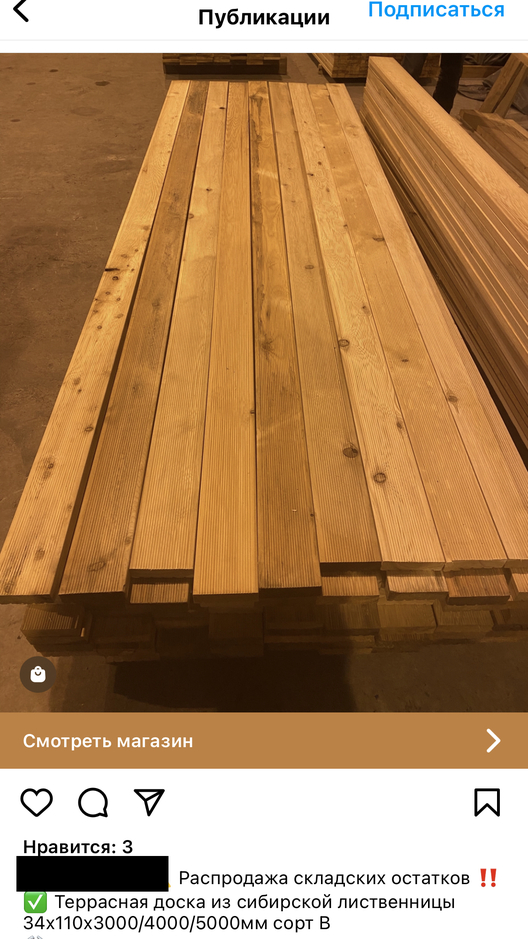

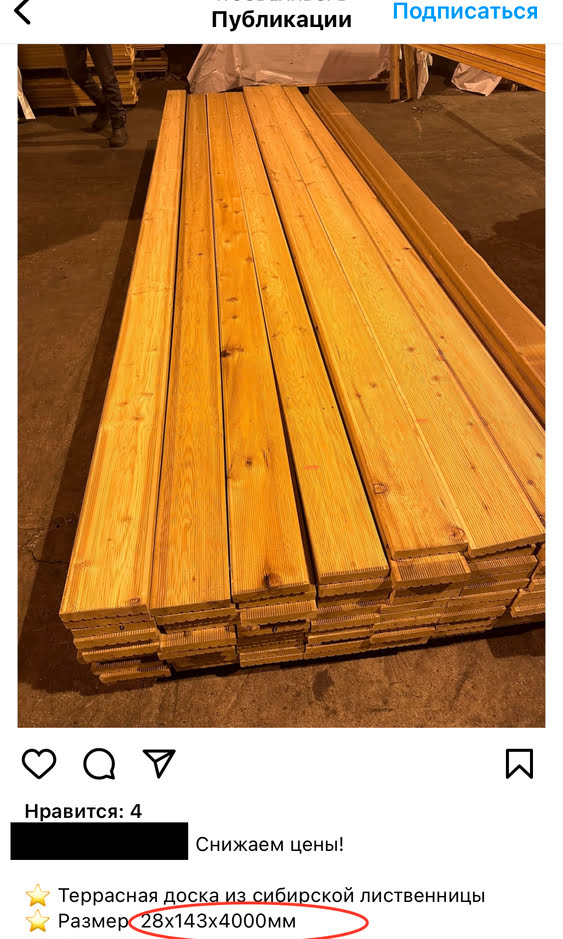

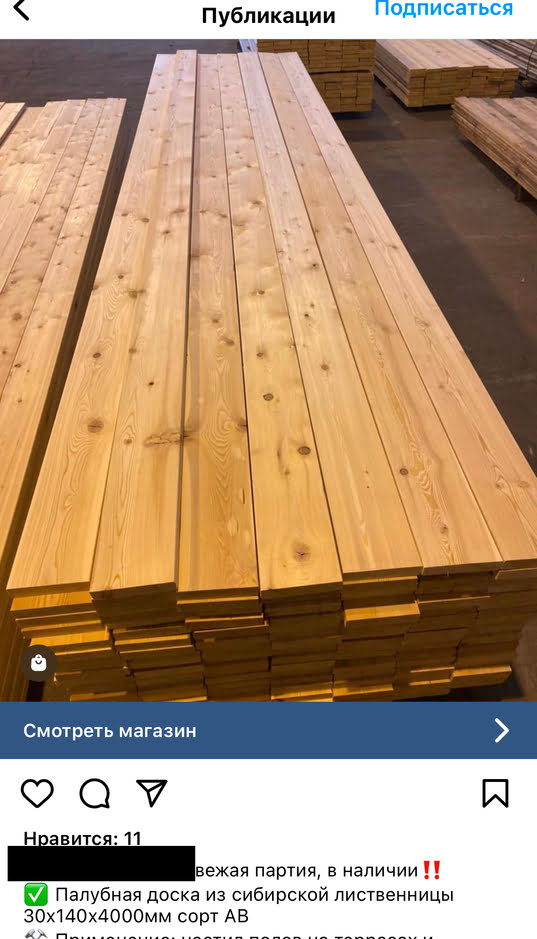

In the selection of photos Leroy Merlin terrace board top left, the other three examples are from the internet:

Deciphering the decking dimension conundrum.

So, what’s the root cause behind this myriad of dimensions? Let’s break it down:

Variability in Production Standards: The market indeed flaunts decking boards of varying sizes. You'll find widths like 140mm, 142mm, 143mm, and even 145mm, alongside thicknesses such as 27mm, 28mm, and 30mm. This diversity primarily stems from the unique production equipment employed by different manufacturers.

The Social Media Effect: Then we have the less informed netizens—accounts managed by individuals more enchanted by vibrant graphics than factual precision. Such platforms can inadvertently perpetuate inaccuracies. Add to this the classic 'telephone game' phenomenon, where information gets increasingly distorted with every iteration. The result? "Facts" that may have meandered far from their original truth after a series of reposts and likes.

The illusion of "Wood Manufacturers" in the digital age.

Venturing further into the convoluted corridors of online wood markets, another challenge surfaces: the self-proclaimed "wood manufacturers. The digital realm is replete with entities wearing the 'manufacturer' badge. However, in many cases, they're merely sellers or resellers, sourcing their inventory from a multitude of producers, each adhering to their distinct specifications.

A common scenario: dream terrace turning into a nightmare.

Let's paint a picture. You're brimming with excitement, eager to bring your dream terrace to life at your countryside retreat. With trusty Google at your fingertips, you begin the quest for the perfect decking. And there it is—a vendor promising precisely what you've been seeking. You dial in:

You: Hello! I'm in need of larch decking, about 200 m2. Can you deliver by tomorrow?

Salesman (panicking internally, thinking of empty shelves and bonuses from fulfilling the sales plan): Absolutely! We always keep a ready stock!

Your journey into the world of decking has just taken a twist. With only 150 m2 in his inventory, the salesman, in a bid to seal the deal, ropes in an associate from another marketplace. A special price is negotiated, and voilà—you have your 200 m2! But, here's where the plot thickens: while 150 m2 is of the size 27x140, the additional 50 m2 measures 28x142.

Might seem like a negligible difference on paper, right? Think again.

Each manufacturer has its unique drying technique for the boards. While one might adopt a quick, cost-effective approach, another might invest time ensuring quality drying. Fast forward to a year later, and you're confronted with an alarming sight: your meticulously designed terrace exhibiting signs of a "countryside jig". The boards are warped, cracking, and seemingly shouting out warnings about the unpredictable nature of larch.

The Takeaway: When setting the stage for your dreamy terrace, steer clear of enticing market offers. Or else, be prepared for that dream to transform into a timber fiasco!

Decoding the mystery of 110 mm and 115 mm decking widths.

The dimensions 110mm and 115mm are notably atypical when it comes to standard board widths. So, what gives these measurements their unique standing? Let's delve deep.

- The genesis - the raw materialCertain manufacturers offer boards in these specific sizes, and often, it's attributed to the nature of the raw material itself. The wood billet might be uniquely sawn, resulting in these unconventional dimensions.

- The role of sosial media & digital platformsIt's not uncommon for misinformation to float around on digital platforms, especially social media. Many a time, non-experts, ranging from enthusiastic copywriters to graphic designers, curate content without deep-rooted knowledge of woodworking. Relying on unreliable sources or mere oversight can lead to the propagation of such "legendary" sizes.

- Emergence of non-standard dimensionsEvery so often, non-traditional sizes, like the 110mm, make their way into production. This could be attributed to the board being sawn to achieve a superior grade or various other reasons. Such uniquely sized boards might be made available as single pieces or limited batches.

A note to the woodworking fraternity.

For architects, designers, and all wood enthusiasts, it's essential to be aware: if you're on the hunt for a 110mm board, the quest might be slightly extended. It could even require a direct approach to the manufacturer. Furthermore, the pricing of such distinctively sized boards may differ from the more ubiquitous dimensions. In essence, while rarity has its allure, it often comes with its own set of challenges.

The millimetre dilemma in woodworking: precision matters.

In the realm of woodworking, even minute variations in dimensions can drastically impact the end product. Let's explore the importance of such precision, particularly when it comes to the thickness of boards.

1. The thickness conundrum.

The subtle differences in board thickness can sometimes be the root cause of significant issues. For instance, while your choice of board might be a sturdy 35 mm in thickness, another manufacturer's version might be a slimmer 34 mm or even less. Such seemingly minor discrepancies can snowball into challenges, especially during the assembly phase.

2. The decking board debacle: a scenario.

Picture this: You've embarked on a decking project and midway through, you run out of boards. A quick run to the local supplier gets you additional boards, but from a different manufacturer. Alas, the new boards are 5 mm thicker. Once you place this thicker board alongside the others, it protrudes conspicuously.

For decks, you might consider milling the board to match the rest, but that requires specialized equipment and a precise hand – assets not every builder possesses. The challenge amplifies if you're working with a corduroy board, which features chamfers on the back side, making resizing even more intricate. The situation worsens if you're installing flooring on a concrete base, such as in an apartment setting.

What Tools Are Truly Precise?

The Essence of Precise Measurements: Choosing the Right Tools

In the intricate realm of measurements, the aphorism, "The devil is in the details," takes on a profound significance.

The accuracy of any measurement hinges on the instrument you're using. Most of us have chuckled at those internet memes where two tape measures from the same store provide different readings. But it's not just tape measures that can trip you up. Borrowing a plastic ruler from a first grader's school supplies, utilizing that old corner square in the garage, or relying on your favorite sewing tape might not yield the best results.

Take, for instance, our decking. A tape measure, depending on its angle, could give you readings that vary by a couple of millimeters. One might read 142mm, another 140mm, and yet another might fall short of even that. But with a caliper, the dimensions resonate with a level of accuracy that's unmatched.

Calipers: the gold standard in precision!

Enter the world of calipers – a paradigm shift in the domain of measurements. While rudimentary tools might give you a ballpark figure, calipers delve into the minutiae. They offer accuracy down to the millimeter, ensuring that what you measure is as close to the real dimension as possible.

IMPORTANT!

The intricacies of measuring planed timber products with radius elements.

Introduction to planed timber products with radius edges.

We live in an era where attention to detail is crucial, especially in the construction and design sectors. Planed timber products, including decking, deck boards, cladding: rainscreen, shadow gap, shiplap, T&G profile battens, and more, are renowned not just for their aesthetic appeal but also for their functional characteristics. These radius edges provide structural strength, minimize potential injuries, and ensure an even distribution of loads.

The importance of rounding radius in timber products.

The rounding radius of a planed product can differ significantly. Various factors, including production technological parameters and the desired aerodynamic or aesthetic characteristics, influence it. This makes measuring the radius an essential task requiring specialized tools.

Tools for accurate measurement.

Using radius rulers or profilometers is paramount in capturing the exact geometry of a rounded edge. These instruments eliminate potential errors that might arise when using conventional rulers or tape measures.

It's essential to get this measurement right, as an inaccurate reading can influence the final installation or design of the product.

Understanding wood as an anisotropic material.

Wood is unique. Its anisotropic nature means its properties vary in different directions. This trait requires special attention when measuring a rounded radius. Depending on the direction of wood fibers and the moisture content, the radius can evolve or become distorted over time, influenced by a myriad of factors.

Variability among different wood species.

Not all woods are created equal. Different species possess distinct physical and mechanical characteristics. For instance, the rounding radius of pine might react differently to external factors compared to larch products. This variability underlines the importance of understanding the material's properties when working with radius elements.

Comprehensive measurement: a blend of geometry and material properties.

A successful measurement process considers both the geometric parameters and the innate properties of the wood. By acknowledging the full picture, professionals can ensure accurate and reliable results. This precision becomes invaluable, especially when embarking on designing and setting up intricate wooden structures.

The nuances of measuring wood products with radius elements.

The world of planed timber products with radius edges is deep and multifaceted. Understanding the importance of rounding radius, equipped with the right tools for accurate measurements and acknowledging the unique properties of different wood species, is the key to mastering this domain. By taking a holistic approach to measurement, considering both geometry and material properties, one can achieve unparalleled precision - a cornerstone for successful design and installation projects.

GOST: a deep dive into Russian standards.

For many, the term 'GOST' is synonymous with quality and consistency. Originating from Russia, GOSTs (State Standards) are a set of standards that provide guidelines for an extensive array of goods and services, ensuring they meet specific quality benchmarks.

- What GOST Doesn't Cover. While GOSTs cover a wide spectrum of goods and services, it's important to note that they don't encompass everything. A prime example is the realm of woodworking. There are no designated GOSTs for decking boards, planken, floor boards, and wagons. The discrepancies in board dimensions, which we've previously delved into, underline the absence of a standardized GOST in this domain.

- GOSTs: Champions of Precision and Quality. Whenever precision and quality become paramount, GOSTs rise to prominence as trusted companions. This dedication to detail even extends to the tools used for measurement. GOST 166-89 and GOST 7502 are just a couple of examples from a plethora of standards governing the precision and reliability of measuring instruments. Hence, before you embark on any measurement task, it's pivotal to ensure that your instrument aligns with the requisite GOST specifications.

- Measuring for sawn timber: GOST 6564-84. Understanding the intricacies of measuring lumber? GOST 6564-84 is your beacon. Consider it a comprehensive guide to all matters related to measuring lumber and billets. This standard clarifies nuances, techniques, and best practices, ensuring accurate and consistent measurements.

Standards, like the GOSTs mentioned, are instrumental in maintaining consistency, precision, and quality across industries and regions. Just as Russia utilizes GOSTs to ensure reliable measurements and dependable quality, other nations also have their distinct sets of regulations and standards to uphold industry benchmarks. However, it's crucial to remember that while standards may vary from one country to another, the inherent properties of natural materials remain consistent. For instance, the intrinsic characteristics of larch decking boards will not differ whether they are exported to Germany, Austria, England, or even the North Pole. This universality underlines the importance of global understanding and respect for standards, but also the recognition of the immutable qualities of nature's offerings.

Navigating the nuances of wood dimensions.

Size variations: a standard affair.

When you come across different measurements for wooden boards from various manufacturers, it's essential to remember that this isn't necessarily a mark of error. Manufacturers have their unique standards, production methods, and machinery which can lead to slight variations in product dimensions. Moreover, wood, being a natural material, has an inherent tendency to alter its size in response to external factors like humidity, temperature, and pressure. Hence, small variations are not anomalies; they are characteristic features of wooden products.

A Word of Caution: Choosing the Right Vendor

The digital age, while bringing a plethora of conveniences, has also paved the way for misinformation. The woodworking market is no stranger to this. Many vendors, in an attempt to quickly set up shop, often replicate information from competitor sites without adequate validation. There have been instances where sellers have gone to the extent of using pictures from other businesses, presenting them as their own. It's pivotal for consumers to approach such information with skepticism. Always do your homework—research the vendor, verify their credentials, and when in doubt, seek recommendations or reviews. Making an informed choice will save you from potential pitfalls and ensure that you get the best value for your money.

The Subtleties of Siberian Larch Cladding: A Journey into Precision: "The Cost of Millimetres and Degrees."

Imagine diving deep into your renovation project, seamlessly placing each 20x145mm Siberian larch rainscreen cladding. However, just as the finishing line appears in sight, you discover you're short on cladding boards. A quick call to your trusted supplier reveals they're out of stock. Panic sets in.

Scouring different markets in desperation, a startling realization hits you: when purchasing, you assumed all rainscreen claddings were identical. But now, in the thick of the project, it becomes glaringly clear that your cladding has an atypical 60-degree bevel angle, while the majority sport the more conventional 45-degree one. This might sound trivial, but this angle is pivotal, especially when it comes to the intricate window corners and end joints. A deviation here could mar the entire aesthetic appeal you envisioned for your space.

Tracking down a manufacturer who caters to this unique specification transforms into a daunting task. Many seem to exist only virtually, while others are passed along by word-of-mouth. And when you think of ordering an extra 10-20m² from a distant location like Irkutsk? It feels like an insurmountable challenge.

In woodworking, it's often the minute details that determine the success of a project. As this tale reveals, it's always crucial to be thorough from the outset to ensure a smooth journey to completion.

In Moments of Uncertainty, We're Here to Assist

Facing such intricacies can be daunting, and many might feel the urge to give up. However, we pride ourselves on our meticulous attention to detail, which often becomes the beacon of hope in these challenging situations. Our commitment is to ensure that you're never left stranded. So, if you ever find yourself grappling with such dilemmas or are in need of expert advice, remember that our doors are always open. We aspire to equip you with the knowledge that will shield you from potential pitfalls, ensuring your woodworking journey remains smooth and satisfying.

Today, we journeyed through the intricate realm of larch decking, unraveling the nuances of its dimensions. Beyond this, it's pivotal to remember that every millimetre and degree plays a role, whether it's in planken, wagoning, imitation timber, or quarter board. May your choices always be well-informed, bringing nothing but delight! We trust our insights and expertise served you well.

Warm Regards,

The Timber Expert Team