Wood Cladding Transformation: The Astonishing Before and After - From "Never in My House" to "Must-Have"!

Transforming Your Space with Larch Cladding: A Guide to Quality and Craftsmanship

Dear readers!

As a woodworking company, our specialization lies in the main aspects of wood processing. We want to make it clear that our services do not extend to preparation and treatment tasks such as painting, applying wood oil, paint, or impregnation primer. Importantly, our goal is not to attract customers to wood painting services. Instead, we focus on sharing valuable knowledge and techniques that can help avoid unnecessary expenses in these areas. We also do not endorse any specific manufacturers of wood cosmetics, emphasizing that the effectiveness of wood treatment depends greatly on the preparation of the wood and the application technique, rather than just the product used.

When it comes to making a lasting impression, appearances do matter. But can we truly judge everything solely by its exterior? Let's embark on a journey into the realm of craftsmanship and discover how this can elevate even the most unassuming material, such as larch.

Picture larch, an unassuming and nondescript board that many might overlook as a material not worth a second glance. However, there's a remarkable twist to this narrative: with the right approach and skilled hands, this unremarkable board can be transformed into a genuine work of art. After all, not everything that gleams is gold, and not every knot-free board signifies quality.

In this story, there's no room for deception. We will explore how to avoid falling victim to misleading practices. Some manufacturers and sellers, driven by profit, resort to staining low-grade wood to mimic the appearance of premium species. They promise boards of exceptional quality, but in reality, they are merely disguising subpar materials.

Now, let's get to the crux of the matter: how can you distinguish genuine quality without breaking the bank? By investing in high-quality materials from the outset and putting in meticulous effort, you can transform even the most unattractive board into a masterpiece. Whether it's larch cladding, Siberian larch cladding with T&G profile, or larch paneling, these are not just construction and finishing materials; they are canvases for your creative vision.

The Artistry of Larch Cladding

Unlocking the Potential: Larch, often overlooked, possesses incredible potential. With the right techniques, it can be crafted into stunning cladding that enhances the aesthetics of any space.

Quality Matters: Be wary of deceptive practices in the industry. Some unscrupulous suppliers may use low-grade wood, artificially altering its appearance to resemble premium timber. To ensure you get what you pay for, prioritize quality from the outset.

Crafting Masterpieces: With dedication and skill, even the most unattractive boards can be transformed into works of art. Explore the possibilities with larch cladding, larch decking, or stil wagons as your creative canvas.

Choosing Genuine Quality Over Deception

Identifying Authenticity: Don't be fooled by appearances. To ensure you're investing in authentic, high-quality materials, look beyond the surface. Seek out reputable suppliers who prioritize quality over deception.

Investing in Excellence: Quality is worth the investment. By choosing top-tier materials and employing skilled craftsmanship, you can elevate your project to the next level.

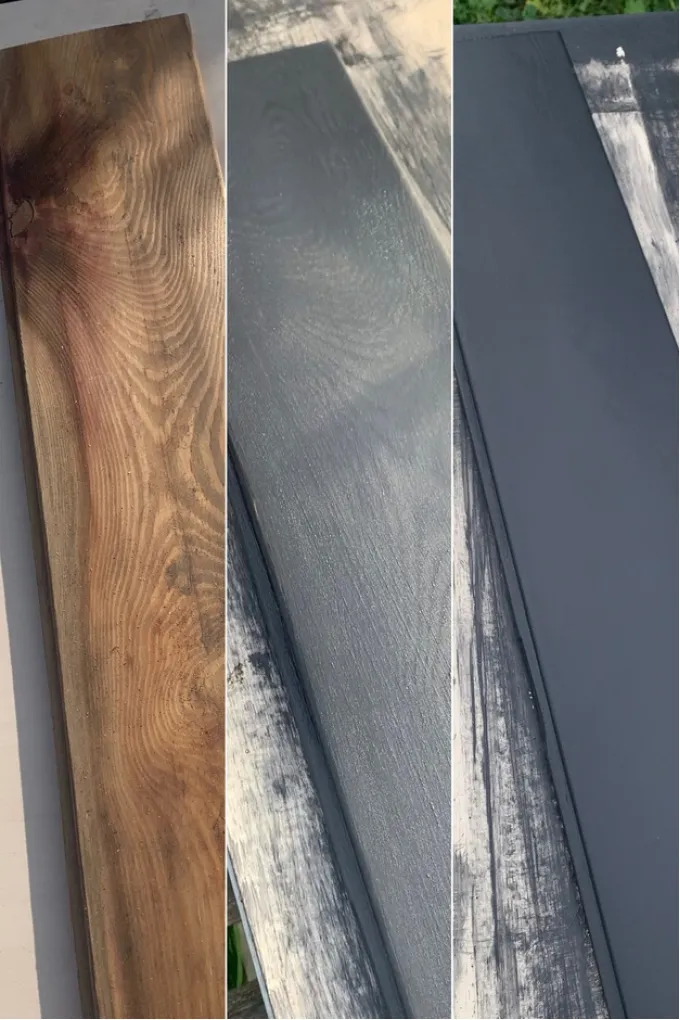

Larch Cladding: From "I'll never buy one of these" to "I want one of these"

In conclusion, larch cladding, when handled with care and expertise, has the potential to transform your space from unremarkable to extraordinary. Don't let deceptive practices deter you from experiencing the beauty and authenticity of this versatile material. Instead, invest in quality, embrace craftsmanship, and turn even the most unattractive boards into captivating works of art. Whether it's larch cladding, Siberian larch cladding with a T&G profile, or larch paneling, your creative vision can truly shine with the right approach.

Exploring the Reality of Wood Painting: From Marketing Promises to True Craftsmanship

When it comes to painting wood, the market is flooded with promises of top-notch treatment in specialized chambers and workshops. However, the reality often falls short of these claims. Paint is applied hastily in back rooms, and after a year or two, it can start to peel or blister. In this article, we'll unveil the secrets of how low-grade wood can be transformed into a product labeled as 'Extra' grade, potentially causing you to overpay for painted boards without even realizing it. Our primary focus is on achieving paint quality with your own hands, which can sometimes surpass what the so-called 'professionals' offer.

In a world where social media trends dictate the tools and techniques for achieving perfect woodworking results, it's easy to get lost amid the overwhelming advice and recommendations. We see advertisements for expensive brushes and hear claims about the necessity of sprayers, often leading us to purchase items that eventually collect dust on pantry shelves.

But what if we step back from the extravagant promises and turn to time-tested methods? That's precisely what we did with larch cladding, a material often overlooked due to its unremarkable appearance but possessing excellent quality characteristics.

Today, we'll take you through the transformation of larch cladding - from its unattractive state to a completely refreshed appearance. The most remarkable aspect is that we achieved this transformation with just a few simple tools that can be found in every home. We used ordinary paint brushes, a bottle with a cut-off neck to dilute the paint, and we skipped solvents and sprayers. Instead of specialized sponges, we even used the same sponge we use for washing dishes.

Beyond Conventional Guides: Transforming Larch Cladding with Minimal Tools

This article won't follow the typical script of a painting or wood preparation guide. We won't delve into discussions about the best paint to choose or whether the surface requires priming before painting. The number of paint layers and drying times, while crucial, varies depending on the specific project and desired outcome.

Our aim is to demonstrate that you don't always have to conform to the latest trends to achieve impressive results. Sometimes, making the most of what you already have on hand, along with a touch of creativity and effort, can lead to unique and high-quality outcomes. Before us stands a seemingly unattractive stack of larch cladding. Modest in appearance, it might not catch the eye of a crowd, but don't rush to dismiss it.

Here, we'll reveal how this unassuming material can be transformed into something remarkable using basic tools, ingenuity, and a commitment to craftsmanship. Discover the beauty that lies beneath the surface of larch cladding and learn how you can achieve exceptional results with simplicity and dedication.

From Dirt to Princes: Step-by-Step Guide to Transforming Larch Cladding

Let's embark on a journey of transformation with larch cladding, specifically Siberian larch cladding with T&G profile. Our first step begins with selecting a single board from the pack, and the initial check reveals its perfect moisture content.

We pay special attention to a prominent knot on the board, handling it with extra care. It's these unique details that impart character and individuality to our products. Knots play a pivotal role in determining the wood grade, significantly impacting material costs. While some prefer 'extra' boards with minimal knots for their uniform and 'clean' appearance, others appreciate the beauty that these natural wood patterns provide. Occasionally, knots are expertly incorporated to highlight the material's naturalness without resorting to higher-priced alternatives. But more on camouflage in a moment...

The next phase involves preparing the board for transportation. We'll cut it to fit into the trunk of a standard passenger car. However, our efforts won't stop there. We'll further divide the board into multiple pieces to demonstrate how a single board can be transformed into something greater, showcasing its inherent potential. This marks the initial stage of our transformation journey.

Upon completing the sawing process, we observe the exceptional quality inside the larch cladding. Unlike pine or spruce, which are susceptible to rot, larch stands as a symbol of strength and reliability. This is precisely why it deserves our attention and dedication.

In our exploration of larch cladding, we are unveiling the hidden treasures that lie within this unassuming material. From the perfect moisture content to the intricate knots that add character, larch cladding holds the promise of transformation. Stay with us as we continue this journey and reveal how to make the most of every inch of this remarkable wood, turning it into something extraordinary.

So once again, we turn our attention to that same knot!

Sanding the Wood

With the sawing process complete, it's time to shift our focus to a crucial step: sanding.

Take a look at the larch cladding, Siberian larch cladding T&G profile in the photo before sanding—a vital stage in working with any board, regardless of its grade.

Whether it's a decking, terrace board, planks, or wagons, sanding is an indispensable step. Sanding serves to open the pores of the wood, enhancing the depth of penetration for protective compounds, ensuring a secure bond with paintwork materials, and ultimately reducing paint consumption. Neglecting sanding today could lead to costly repairs tomorrow. Don't be swayed by those who suggest otherwise; sanding is a guarantee of long-lasting quality.

Even if you don't have access to a power sander, that's no reason to abandon the task. We sanded one of the joinery pieces by hand, a process that undoubtedly demands more time and effort but still yields excellent results.

After sanding the board and meticulously removing all the dust, we are presented with two distinct images: the board before sanding and after.

These images clearly illustrate how such a straightforward treatment can significantly enhance the material's appearance.

In the realm of larch cladding, including Siberian larch cladding with a T&G profile, sanding is the key to revealing its true potential. It's a step that should never be skipped, regardless of the wood's grade or the tools at your disposal. The transformation brought about by sanding is evident as we witness the remarkable improvement in the material's appearance.

I'm an artist, and this is how I perceive it!

Now, let's dive into the exhilarating process of painting. For this task, we've opted for German düfa wood impregnation with tinting. This product not only shields the wood but also imparts the desired hue. We exclusively used this product—no complex techniques or additional materials were needed.

The impregnation is meticulously applied layer by layer, ensuring that each layer dries thoroughly before the next one is applied. This meticulous approach guarantees superior protection and a rich depth of color.

Throughout the process, we bring to mind and apply a few trade secrets acquired during years of practice and woodworking training in Europe. These invaluable insights are the legacy of seasoned craftsmen. However, as previously mentioned, today's focus isn't a comprehensive painting tutorial; rather, it's a demonstration of the potential for transformation.

A comprehensive exploration of the intricacies of woodworking demands its own dedicated time and attention, and we will save that for future discussions. For now, our aim is to spotlight the latent potential within each board and illustrate how remarkable results can be achieved with simple means.

We exclusively utilized German wood impregnation, eschewing any primers or alternative products. Following our meticulous painting and transformation efforts, we allowed the woodwork to dry.

The outcome proves truly impressive. Let's examine it from every angle. The treated surface reveals an exquisite grey hue that metamorphoses the wood, bestowing upon it a luxurious and contemporary aesthetic. This color not only elegantly conceals minor imperfections, including knots, but also incorporates them into the material's unique character.

One side

Another side

Returning to the knot, a careful comparison of the photos before and after the impregnation application unveils a magnificent transformation. The once conspicuous knot now appears subtle. When observed from half a meter away, it becomes nearly imperceptible, only faintly visible from specific angles. On the other hand, from a distance, the knot becomes entirely inconspicuous. This illustrates how the meticulous craftsmanship of our woodworker blurs the boundaries between the innate beauty of wood and skillful transformation.

Choosing this wood treatment for interior or facade design not only adds sophistication and style but also accentuates the distinctive qualities of wood, transforming each piece into an exclusive and exceptional object.

Notably, the grey shade, which stands as a prominent trend in contemporary interior and exterior design, symbolizes minimalism and elegance. It has gained particular popularity in European countries such as Germany, Austria, Sweden, and Norway, as well as major cities like London. In 2023, there has been a surge of interest in all shades of grey, especially in building facades, where grey tones are becoming increasingly prevalent. Interior elements are also adopting this color palette more frequently. This trend enables the creation of stylish and modern spaces, making them accessible without the need to overspend on expensive materials.

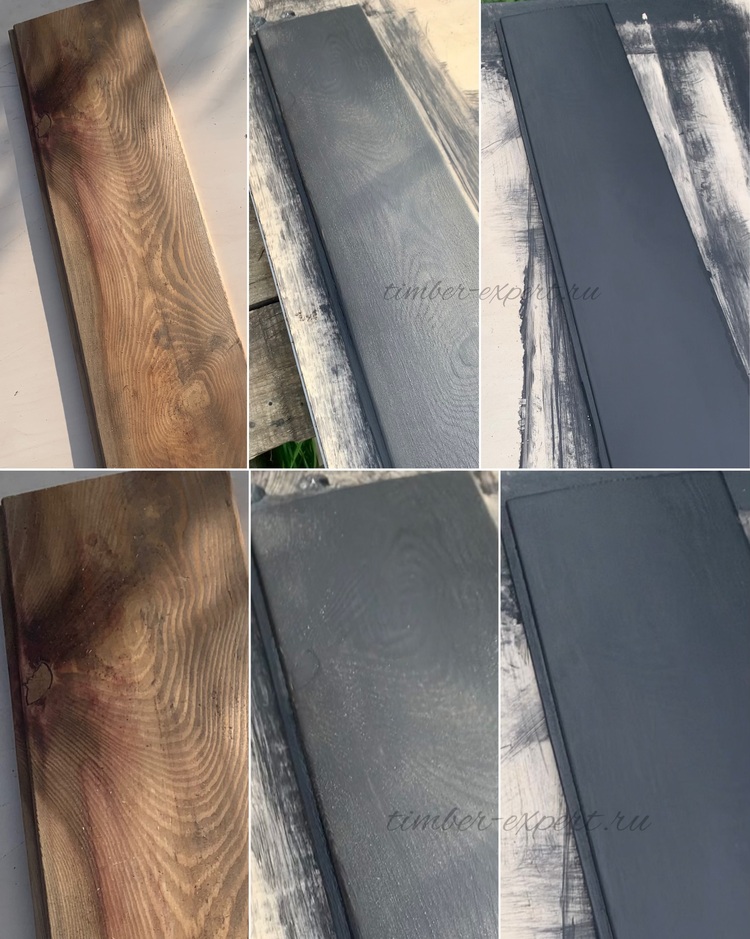

Day 2 "Lady in Black"

In the realm of wood treatment and transformation, pushing boundaries is not just a choice, but a necessity. This ethos was perfectly embodied in our latest project, "Lady in Black." Initially, it started as a conventional process of impregnating larch cladding. However, after allowing a full day for the initial layer to dry, we were inspired to delve deeper into the exploration of color and texture, venturing further than originally planned.

Intermediate Sanding: A Critical Step in Wood Transformation.

The journey to achieving "Lady in Black" was intricate, involving crucial steps often overlooked. A key stage was intermediate sanding. This wasn't just any sanding process; it was meticulous and deliberate. Using fine sandpaper (150 grit or lower), we gently removed the raised wood grain. This step was pivotal to ensure the next layer of impregnation adhered flawlessly, while also preserving the quality of the first impregnation layer.

Global Techniques for Local Excellence

Our method is a blend of global woodworking wisdom, integrating knowledge and practices from industry leaders in Austria, Germany, Sweden, the USA, and other countries. This international expertise allowed us to reach new heights in wood coloring and protection, a fact evidenced by the photographic documentation of our work.

Deepening Color

Post-sanding, we embarked on further color deepening.

The subsequent impregnation layer introduced a richer, more intense hue. It didn't merely add color; it refined the existing layer to a smooth, polished finish. Once dry, the result was "Lady in Black" – a finish that transcended the typical black. It boasted a unique, leather-like texture, setting it apart as an extraordinary piece.

From Original to Transformed: A Comparative Analysis

To fully grasp the depth and artistry of our work, comparing the original larch cladding to the two-day transformation was essential. Paying particular attention to elements like knots, the dramatic effect of our transformation was evident.

Additional photos taken days later of untreated board sections further showcased our commitment to craftsmanship.

Debunking Myths: The Illusion of Black as a Concealer

The prevailing belief that black paint can hide all of wood's imperfections was put to the test in a notable example. When others attempted to replicate our process by masking knots on larch cladding with black paint, the results were illuminating. As seen in the provided photo, the effort to conceal the knots unexpectedly backfired. Far from hiding the imperfections, the black paint accentuated them, highlighting rather than obscuring the knots.

This instance serves as a clear demonstration that simply opting for a darker shade of paint is not a guaranteed fix, especially when it involves masking the natural features of wood. It emphasizes that the desired outcome in wood treatment is less about the color choice and more about the approach and expertise applied. Proper technique and skill are vital in honoring the natural beauty of the wood while achieving an aesthetically pleasing finish.

Experimenting with Shades and Techniques

In our exploratory phase, we segmented a long board to demonstrate various shades and treatment methods. Plans are underway to experiment with lighter, white, or transparent tones, showcasing the impact of different colors on the wood's appearance.

Simplicity in Tools, Complexity in Outcome

The remarkable transformation in "Lady in Black" was achieved using simple tools. Standard brushes, repurposed items for paint dilution, and even a dishwashing sponge for color correction were part of our toolkit. This approach underscores the notion that creativity and innovation can often surpass the need for expensive, specialized equipment.

Beyond Woodworking: Showcasing Our Versatility

While primarily a woodworking company, our expertise goes beyond simple painting or oiling. Our deep understanding of wood and various woodworking techniques sets us apart, offering a level of insight and quality that transcends traditional processes.

Join us on our Telegram channel for an in-depth view of the "Lady in Black" project, complete with daily photos and videos. Witness how we transformed ordinary wood into an extraordinary work of art, layer by layer, ultimately achieving a deep, leather-like black finish aptly named "Lady in Black."

Lumber in Figures: Cost, Quality, and Grade Analysis

When delving into the world of lumber, particularly Siberian larch T&G cladding measuring 15x115 mm, a fascinating comparison of costs and quality emerges, especially when examining retail prices in Russia. With the euro to ruble exchange rate on 11.11.2023 being 1 euro = 98 rubles, let’s break down the figures.

The average price of such Siberian larch T&G cladding falls between 8-9.15 euros per square meter. This pricing aligns with grade C lumber, which is considered the lowest grade and most affordable option. Despite its lower price and less appealing appearance compared to higher grades, this grade C lumber doesn’t possess significant defects like through cracks or large knots, which are typically permissible in this grade. In terms of quality, it surprisingly exceeds what one might expect from a grade C classification.

For a comparative perspective, consider the following grades of the same size Siberian larch T&G cladding:

Grade AB: Features an unlimited number of live knots up to 30-40 mm and costs about 13.22 euros per m².

Grade Prima(А): Contains 1 knot up to 10 mm per 1 running meter, priced at 19.33 euros per m².

Grade Extra: Completely knot-free, it commands a price of 27.4 euros per square meter.

An interesting revelation from our experimentation is the ability to achieve a visual effect similar to the higher grades Prima and Extra using more affordable lumber. When utilizing dark colors and covering paint, the more economically priced lumber can mimic the appearance of these premium grades.

This raises an important question for consumers and professionals in the lumber industry: Is it worth paying extra for higher-grade lumber when a similar visual outcome can be attained with more affordable options? It’s crucial to note that such opportunities for cost-effective yet visually appealing solutions don't always present themselves in our assortment.

In conclusion, while higher grades undeniably offer certain aesthetic and quality benefits, the potential to create a similar visual effect with lower-grade, more affordable lumber provides a compelling argument for those looking to optimize their budget without significantly compromising on appearance.

Timber Expert Wood Processing Plant - Crafting Excellence in Wood