Siberian Larch Beams and Slats Buying Guide: Everything You Need to Know About Sizes, Grades, and More

Siberian Larch beams & laths: the mission is to find understand the sizes and grades, calculate and calculate, buy and do not overpayWhat's the Difference?

Let's start by clearing up the terminology, which often causes confusion among both professionals and enthusiasts. Many people refer to something similar to a lath as a "lath facade," "partition," or "ceiling," assuming it's a lath. But it might actually be a beam! And vice versa, where beams are used, people talk about laths. This also applies to lags, often called laths, although they are, in fact, beams. The confusion often arises from builders, bloggers, and sellers who, without deep knowledge of woodworking, call elements whatever suits them, and then everyone else repeats it. Therefore, let's not complicate matters. We will combine beams and laths into one big family – "love and unity." The essence, sizes, purchasing issues, and sorting we will discuss apply to both. In this article, we will talk exclusively about dried, kiln-dried, planed beams and laths made of larch. We will use both terms interchangeably to avoid tautology.

The Purpose of This Article

Over the years, we've received thousands of inquiries, with the most popular questions being: "Why can't you make 10-20 pieces? You're not customer-oriented!" "Why can't you make the size I want?" or "Why is the size I need nowhere to be found, and it's so expensive to make?" "Why is it not in stock?" or "Why does it take so long to wait?" These questions are most frequently asked by people looking for larch laths and beams. Therefore, we decided to create this guide to purchasing beams and laths, specifically regarding our enterprise. Here, we will give examples from our customers' projects, which have become benchmarks for many. We are often asked to do the same, and we are happy to share the best practices and results. We hope this guide will be useful and enjoyable to read.

Architectural Fashion Beyond Time

Have you ever wondered why lath facades, ceilings, walls, or partitions cause such excitement? Laths and beams have become a real trend in modern interior and exterior design. Why do architects and designers love laths and beams so much? It’s not just a fashionable trend—it’s a return to time-tested solutions. Larch laths and beams add visual lightness to structures, making them more attractive and interesting, adding vertical or horizontal rhythm to the project. If planed larch or rainscreen has become a bit tiresome, adding something massive and common, laths and beams remain at the peak of popularity, giving interiors and exteriors a special charm. But that’s not the main point. Laths and beams have an undeniable advantage over any type of finishing material, such as larch planking. The narrower the board, the less prone it is to warping, i.e., deformation when humidity changes. While planks may "play," laths and beams, when properly installed and ventilated, retain their shape. This ensures the longevity and stability of structures. Why does this happen? The basis of this phenomenon lies in the physics of wood. When humidity changes, wood tends to expand or contract. The wider the board, the more it is subject to these changes, leading to warping. Laths and beams have a smaller area for humidity changes to act on, which significantly reduces the risk of deformation. Furthermore, proper installation and ventilation contribute to maintaining the shape of laths and beams. They adapt more quickly to changes in environmental conditions, preventing stress accumulation inside the wood and, consequently, warping. Thus, larch laths and beams are a more stable and durable solution for finishing, both indoors and outdoors.

Grades: How We Sort Them

Many builders and people unfamiliar with woodworking believe that beams or laths should be perfect on both sides, without knots and other defects if they are high-grade, such as Extra or Prima. This stereotype is introduced by builders and people unfamiliar with actual production conditions. In reality, nowhere in the world, except for joinery and furniture production, is wood sorted by two sides. It is important not to confuse furniture production and joinery with woodworking and logging enterprises! These are different directions, different equipment, different processes, and, accordingly, different prices and different products at the output!

Sorting Features

The entire wood sorting process is based on two sides—the cross-sections of the beam or lath, the front sides. This is due to the peculiarities of sawing and planing. During the process of turning a board into a finished product, knots and resin pockets are identified. These defects on the back side do not affect the structural strength. You might think or say, "This is horrible! How can this be? This doesn’t suit us!" Some may get indignant and call us "defect makers." But, for example, in a project in St. Petersburg, facades were made of larch beams. We used Extra + Prima grade beams and laths, where sorting is done on two front sides. This means that knots and resin pockets may be present on the other two sides, but no cracks are allowed along the entire length. You can read a detailed review, watch the video, and visit the developer's website and social networks to see the finished facade. If you have any questions, you can learn all the details. Wood sorting is a complex process, and each manufacturer has its standards. There are no GOSTs for sorting dried, kiln-dried, planed products, and the AB grade of one manufacturer may differ significantly from the AB grade of another. For example, Prima grade from one manufacturer may be called A grade from another. These are seller tricks, and it is important to understand that each manufacturer sets its standards.

The entire wood sorting process is based on two sides—the cross-sections of the beam or lath, the front sides. This is due to the peculiarities of sawing and planing. During the process of turning a board into a finished product, knots and resin pockets are identified. These defects on the back side do not affect the structural strength. You might think or say, "This is horrible! How can this be? This doesn’t suit us!" Some may get indignant and call us "defect makers." But, for example, in a project in St. Petersburg, facades were made of larch beams. We used Extra + Prima grade beams and laths, where sorting is done on two front sides. This means that knots and resin pockets may be present on the other two sides, but no cracks are allowed along the entire length. You can read a detailed review, watch the video, and visit the developer's website and social networks to see the finished facade. If you have any questions, you can learn all the details. Wood sorting is a complex process, and each manufacturer has its standards. There are no GOSTs for sorting dried, kiln-dried, planed products, and the AB grade of one manufacturer may differ significantly from the AB grade of another. For example, Prima grade from one manufacturer may be called A grade from another. These are seller tricks, and it is important to understand that each manufacturer sets its standards.

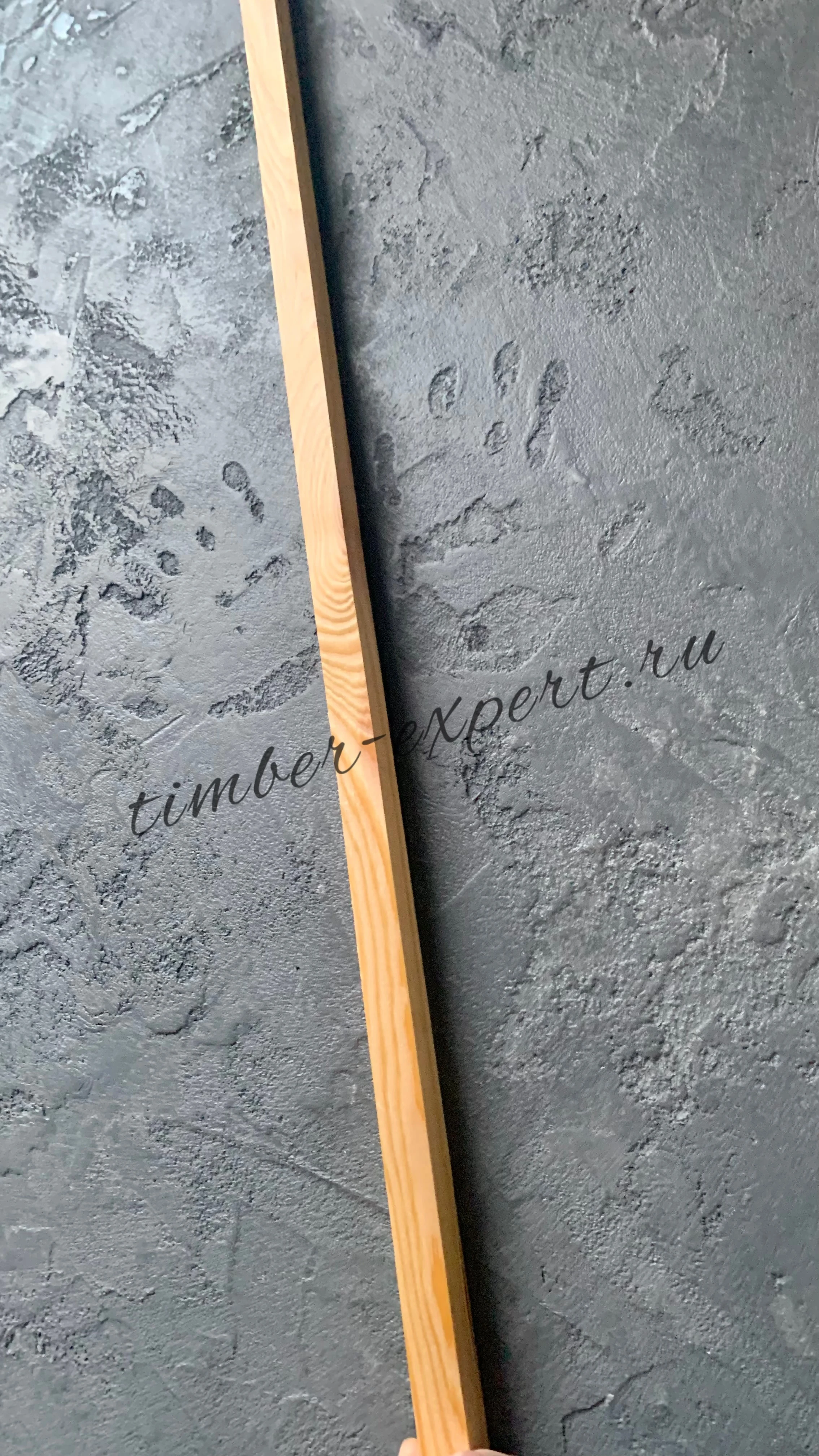

Life Hack for You: Working with Small Cross-Sections

Working with small cross-sections, such as 20x20 mm beams and laths, requires a special approach. Such small beams or laths can break or simply split in half during planing. Therefore, considering our sorting, it is impossible to make grade C on small cross-sections! For tiny beams and laths (e.g., as in the photo and video 20x20), it is almost impossible to make grade AB as many are used to perceiving it. The smaller the cross-section, the harder it is to achieve low quality. Such beams mostly come in Extra or Prima grades. If you don’t have the budget for Extra or Prima, take AB. On a width of 40 mm, there will be few knots, and they will naturally be smaller. And on 20x20, even more so! Look at a 20x20 beam—it’s only 2 centimeters. Any knot +/- of this size means there is no beam—we won’t give you such a one. But on planking or terrace, such a knot will go in AB grade and look great, not seem huge. Therefore, a small cross-section levels the number of knots and their size. Swipe right

Beams and Laths Ordering and Availability

First of all, note that we are not a store or a warehouse! We are a manufacturer. We do not produce "into the void," for stock. All orders are made for a specific customer. We accept orders from 1 m³, and volumes are dictated by the specifics of the production process.

Let's explain this simply. Like Gazprom, which does not focus on servicing a single gas station, our company aims at significant product batches. We cannot fulfill orders for one or several units, as preparing equipment for such small volumes requires efforts comparable to large-scale production. Similar to a flour mill, which does not produce just two packets of flour, we focus on larger orders. To get beams with perfect geometry, a lot of time, effort, and materials need to be invested. The production plan must also include such orders and fit them into the schedule.

Logistics and Planning Example

We supply raw materials in the form of logs by rail from the Krasnoyarsk Territory, so the order quantity matters. It cannot be too little or too much. An example of our customer from St. Petersburg, whose house facades inspire thousands, shows that such projects are planned in advance. We received hundreds of calls with requests like "I want the same," "I need 1000 meters tomorrow." It doesn’t work that way. Material for such a house was calculated and ordered 4 months in advance. Ask the builders and customers—in the reviews. It takes a long time. It can be faster, but those who plan deadlines and quality, plan well in advance. The required quality and sizes are practically unavailable on the market. We also plan to bring a certain amount of materials for projects, dry them, and manufacture them.

Small Orders

Orders for small amounts, such as 2-3 or 5 thousand rubles or 10-20 30 pieces, ARE NOT ACCEPTED! BUT! Possible exceptions! If there is no stock, you can always call and ask. Maybe we are currently or will soon be planing the required size beams or laths, and you can get them in parallel. Or there are remnants from other orders that fit your size or grade. We’ve had cases when they took 2-3 beams. But we do not take on such orders specifically. Orders for larch beams and laths are accepted from 1 m³, depending on several factors: wood grade and your requirements! Lengths and cross-section/size!

Features and Flaws

Better familiarize yourself with the photos of our 20x20 mm samples and the video of our 45x55 mm samples: one side is radial — without a pattern, the other is tangential — with a beautiful pattern. Planed blocks and slats do not always look like this; sometimes both sections can be radial. Watch the process of making a block from larch at our facility in the video. If you are a designer looking exclusively for tangential cuts on all sides for "beautiful patterns, shades, etc.," please contact other specialists. Thank you for understanding and respecting our time and resources. Scroll right to view photos and videos. Swipe right

The next two faces — sections: there are unplaned areas, there are resin pockets. These minor defects do not violate the geometry and integrity. If we are talking about high grades, such as extra or prima, then sorting will be done on two sides, and the rest may have minor defects. If you need a block that is perfect on all sides, there are two options: we can discuss the conditions of manufacture and the price, which will be significantly higher, BUT most likely we will not take on the preparation of furniture stock!

BUT!!! Sometimes these defects are absent on the reverse side! Wood is a living material. A knot may not be revealed, the cutter of the machine may not catch it. So sometimes the blocks will be perfect on all sides — this is not intentional, but rather a stroke of luck. However, we always warn you in advance.

Rounding and Chamfer.

Planed blocks and slats can have 90-degree angles (straight planing) or rounded edges. By default, products are made with a 90-degree angle, as shown in the photo in our article. If you need rounded edges, you must notify us in advance and specify the details!

"To Chamfer! Cannot Forgive!"

The process of chamfering corners is not always a simple and straightforward process like with chamfered planken, for example. The size of the block and slat plays a key role. If your project does not depend on exact dimensions, feel free to experiment with the shape of the blocks. We often make sizes 20x68 and 28x70, which are popular but not listed on the website. These 2 millimeters may vary depending on the availability of materials in production: sometimes it's 68 mm, sometimes 70 mm. Therefore, please discuss these points with our specialists. Consider them in your design to not only maximize cost savings but also to avoid mistakes with the necessary dimensions for your project.

It is important to understand that the process of chamfering corners requires a special approach and equipment. We are ready to make chamfered blocks for you, but this needs to be discussed in advance to consider all the nuances of your project and ensure high quality of the finished product.

Timber Expert Math: How to Calculate Quantities Correctly

Let’s figure out how to correctly calculate the amount of material. Let's look at several different beam and lath sizes and calculate their quantity in a cubic meter.

- Laths 20x40 mm

If not tied to length, there will be 1250 linear meters in 1 m³. Let's see how we got this quantity.

1 m³ = 1,000,000,000 cubic millimeters (since 1 m = 1,000 mm, therefore, 1 m³ = 1,000 x 1,000 x 1,000).

To calculate, we need to convert the cross-section sizes to meters:

20 mm = 0.02 m; 40 mm = 0.04 m

Now we divide the volume of 1 m³ by the volume of one lath: 1 m³ / (0.02 m * 0.04 m) = 1250 linear meters

Now let’s count the number of 4-meter laths in 1 m³: 1250 linear meters / 4 m = 312.5 pieces. But, considering that laths should be whole, we round to the nearest whole number: about 313 pieces. This is necessary to avoid a shortage of material, as a lath cannot be divided.

- Beams 45x45 mm, 4 meters long

Beam cross-section 45x45 mm: 45 mm = 0.045 m

Now we divide the volume of 1 m³ by the volume of one beam: 1 m³ / (0.045 m * 0.045 m * 4 m) = 111.1 pieces

Round to the nearest whole number: about 112 pieces. This is necessary to ensure a sufficient amount of material.

Linear meters in 1 m³: 112 pieces * 4 m = 448 linear meters

- Beams 20x20 mm, 3 meters long

Beam cross-section 20x20 mm: 20 mm = 0.02 m

Now we divide the volume of 1 m³ by the volume of one beam: 1 m³ / (0.02 m * 0.02 m * 3 m) = 833.3 pieces

Round to the nearest whole number: about 834 pieces. This is necessary to ensure a sufficient amount of material, as a beam cannot be used partially.

Linear meters in 1 m³:

834 pieces * 3 m = 2502 linear meters

To correctly calculate the amount of materials, it is necessary to consider:

- Length of the product

- Cross-section of the beam or lath

Simple Calculation Method

Convert the cross-section sizes to meters.

Multiply the cross-section sizes by the length of the product to get the volume of one product.

Divide 1 m³ by the volume of one product to get the number of products.

Example Calculation

Suppose you need 100 laths with a cross-section of 20x40 mm and a length of 4 meters.

Calculate the volume of one lath: 0.02 m * 0.04 m * 4 m = 0.0032 m³.

Multiply the volume of one lath by the quantity: 0.0032 m³ * 100 = 0.32 m³.

Thus, for 100 laths, you will need 0.32 m³ of wood.

Square Meters Calculation

Square meters are better not to count in such calculations. Why? Because it depends on the use and application of beams in your project. Even if you have a facade or wall, laths are not mounted edge-to-edge — gaps are left between them. The size of the gaps also depends on the specific project. Therefore, for accurate material calculation, it is better to count in linear meters.

How to Choose Larch Beams and Laths for Various Projects

Size Matters!

Millimeters matter!

Architects, designers, builders, and everyone thinking about creating something using laths should remember: 1-2 millimeters in cross-section size can increase the project cost by one and a half to two times. The same applies to lengths, but more on that later.

Architects, Designers, and Builders

Consider an example from the comments to our post about laths on social networks. A lath 100 mm wide is more like a board from which they make 90-95 mm wide planking. Anything over 70 mm is usually called planking. These 5-10 mm are used for planing and calibration. Material sizes in woodworking are chosen thoughtfully: a 120 mm board is used for a 100 mm lath. The process includes sawing, drying, and planing, affecting the final size. Non-standard sizes are possible, but standard ones simplify production and reduce costs. A small difference in size, for example, 3-5 mm, can increase the cost. It is important to consult with technologists before starting a project to avoid mistakes and unnecessary costs. Almost always the dimensions of materials are invented without taking into account the real possibilities of the market, because many people mistakenly believe that in Russia there are enough forests and the necessary sizes can always be found and bought. However, when faced with the harsh reality, they either pay much more or abandon the original idea and buy standard planken or whatever is cheaper in stock. As a result, they have to give up what was drawn by the architect on a beautiful rendering.

Afterword by Timber Expert

We have discussed in detail the features of choosing and using larch laths and beams in the context of our production. It is important to understand that each manufacturer has its standards and methods of working. Someone sorts wood one way, someone else another. Sizes and quality of products on the market can vary. Look at the "luxurious" beam and laths from Leroy Merlin.

However, our approach is different!

If you plan to buy larch beams, we will make them for you to order and deliver to any region of Russia. We offer various sizes and grades. Our laths and beams are distinguished by perfect geometry, rich shades, and jewelry processing. Real Siberian larch, unlike that in Leroy or markets, has high density, ensuring strength and durability. You may like or dislike our approach, but we have explained the essence of our work with all the nuances. Our premium Siberian larch beams and laths are perfect for your architectural and design projects, offering unparalleled quality and durability. If you want to read more information about how to boost traffic on your Website just visit