Mastering the Art of Home-Based Wood Drying: Your Comprehensive Guide

Drying lumber. Drying wood yourself.

When it's beautiful May and we have a whole summer ahead of us, and it's summer when wood dries the fastest, if you're going to buy lumber and dry it yourself!

You've come to the right place! This article is for those who want to learn how to dry boards, how to dry wood at home, and understand the intricacies of natural - atmospheric drying.

Wood, like a sponge, has a porous structure that can absorb moisture from the air. The moisture gradation after sawing ranges from 30 to 60%, depending on the type of wood. It is important to prevent lumber from being stored in extremely humid or dry conditions, so as not to run the risk of warping or damaging it.

There are several approaches to bring timber to the required moisture standard. The choice of method is determined according to the needs of the manufacturer or the individual, if he is drying lumber for his own personal purposes. Today we will discuss this method. The atmospheric drying method is probably one of the simplest and most budget-friendly available.

Drying process.

Atmospheric drying is a process carried out not in drying chambers but outdoors in specially organised stacks.

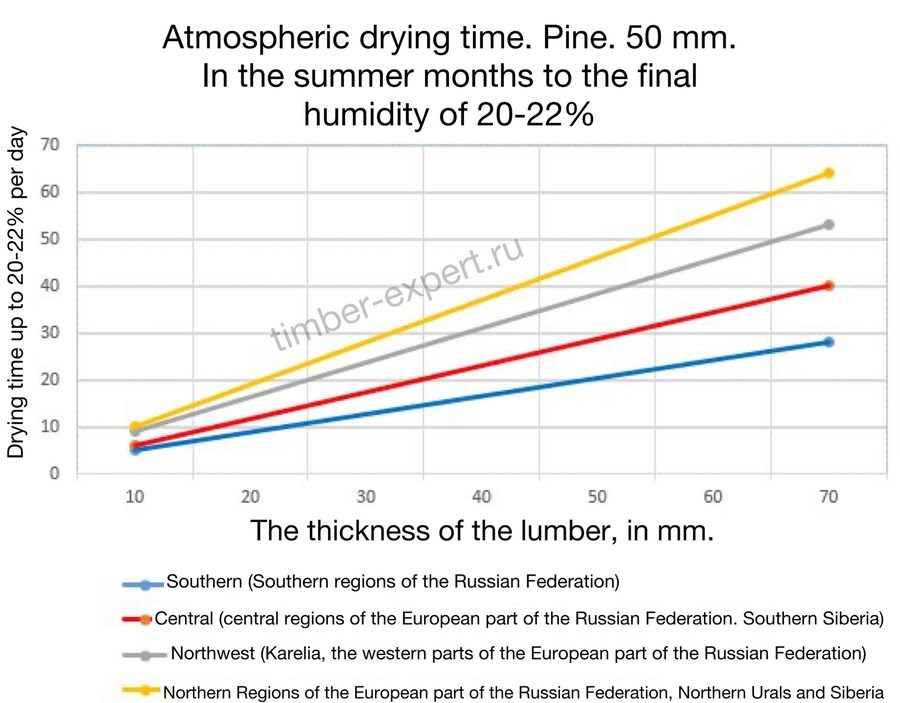

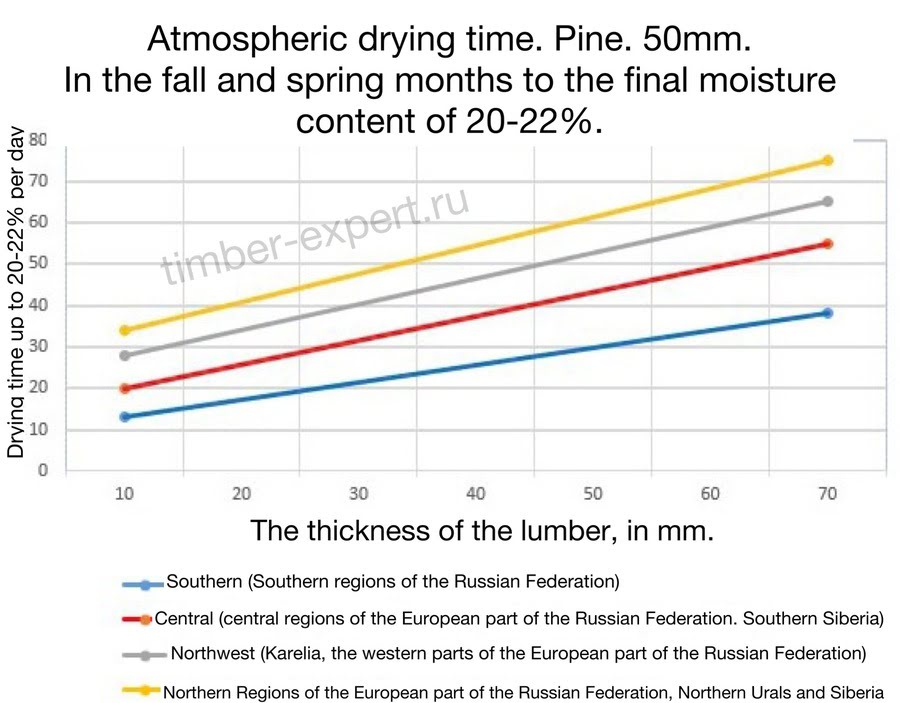

The drying time interval is determined by:

- The thickness of the lumber and its species;

- The time of year (summer or spring and autumn);

- The climatic conditions of the zone (1st, 2nd, 3rd or 4th).

The diagrams below show the approximate drying time for softwood lumber (pine, spruce) to a final moisture content of 20-22%.

For example, in the summer month for pine with a thickness of 50mm the drying period will be around 28 days.

The duration of drying in this way is directly related to the type of wood and the environment. Under favourable conditions, up to 75% of moisture is naturally removed from the wood, and deformation of the material is minimal.

1. For efficient atmospheric drying, it is necessary to carefully select a site to install a solid base of beams, pipes or rails. The site must be level - except for any obstacles in the form of holes, stones, roots, etc.

2. The lumber is placed on a prepared base. Many experts prefer to start the first layer with boards that have a ridge or other defects, if any. Gaps must be left between the boards and the individual layers must be separated by uniform spacers. It is important that the spacers do not extend beyond the board ends.

See how NOT to do this categorically!

So don't do that either

3. Waterproofing is also necessary. Ruberoid or thick film can help. However, overzealousness should be avoided: the wood must be accessible for blowing - ventilation from all sides.

4. By the way, when stacking timber for drying, the ends of boards are usually covered with paint, oiling, lime or PVA glue. This helps prevent the material from cracking.

5. A roofing material is placed on top of the lumber so that when precipitation occurs, water will run off freely without coming into contact with the wood. Do not forget to protect the stack on the windward side: wind and rain unfortunately do not go anywhere.

6. "The roof is the most critical element for a stack! The more secure the roof, the more comfortable you will be when it comes time to dismantle that stack. The roof should be such as to allow free air movement from bottom to top, moist air should not be trapped in the stack or under the roof.

7. It is categorically not recommended to cover the stack with foil, awnings or tarpaulins - sealing is not allowed here. The stack must be visible and ventilated on each side. Do not worry if slanting rain or snow may fall on the stack - this will not damage it. Be sure to attach the roof to the stack so that it won't fly off in gusts of wind. Here's a tip: You can use binding wire for this, which is a fairly reliable and effective method.

8. It's important to remember that the wood in the stack must be accessible for ventilation from all sides. This will ensure that the wood dries evenly and efficiently, avoiding the presence of moisture and preventing possible deterioration of the material.

9. Although heavy rain or snow may seem to be a threat to the stack, in reality the timber is quite resistant to such influences when stored correctly. The main thing is to ensure that it does not come into direct contact with water, so it is important to properly cover the stack.

10. Attention should also be paid to how the roof of the stack is secured. In the event of strong gusts of wind it may come off and fly away, causing unnecessary inconvenience and possibly frightening the neighbours. Therefore, the roof should be secured securely using wire, for example.

What tips would you give?

Wood industry experts advise paying special attention to the correct stacking of lumber when organising atmospheric drying.

1. It is undesirable to stack boards in stacks for atmospheric drying that are more than 1 metre wide.

2. The height of a stack is determined solely by its stability (up to 6-7 m is permissible if the base is made of concrete blocks). If there is a need for several stacks, the distance between them should be 1.5 to 2 metres.

The width of the gaps between the boards on the horizontal plane should be ⅕ the width of the lumber at the edges of the stack, but not less than 25 mm. The width of these gaps should increase from the edges to the middle. In the middle of the stack the gap should be 3 times larger than at the edge.

4. It is advisable to stack timber of the same cross-section to ensure that the gaps between the boards match vertically.

5. The optimum cross-section of shims (overlaps) is 25x40 mm. The number of spacers for a 50 mm board is 4 pieces (for a board length of 4.5 m). The timber of the spacers must be healthy, preferably treated with antiseptic.

6. To prevent distortion of the top, unloaded boards, a sturdy timber can be placed on the stack and tied to the base of the stack with rubber bands. Using wire is ineffective here, as the height of the stack gradually decreases as it dries.

Whether or not to follow this advice is an individual matter. It's up to everyone, based on their experience, to decide which drying method to choose. However, it is important to remember: "the atmospheric drying of wood is not difficult, but there are nuances, and if you ignore them you can spoil a lot of wood and waste a lot of money.

Atmospheric drying is an inexpensive way to dry wood that can give excellent results if used correctly.

FAQs

1. What is atmospheric drying of wood?

Atmospheric drying is a mechanism by which the moisture content of wood is reduced by the ambient air. In other words, it is suitable to organize the wood in an open space, where the wind blows continuously, thus promoting drying.

2. What factors influence the time of atmospheric drying?

The time of atmospheric drying of wood depends on the type of wood, its size and environmental conditions.

3. What are the advantages of atmospheric drying of wood?

Atmospheric drying of wood is an inexpensive drying method that also helps to improve the physical properties of wood.

4. What are the disadvantages of atmospheric drying of wood?

Atmospheric drying of wood can take a considerable amount of time and its efficiency can be affected by weather conditions.

5. How to increase the efficiency of atmospheric drying of wood?

Optimization of drying conditions and regular monitoring of the process can help to increase the efficiency of atmospheric drying.

6. What conditions are necessary for atmospheric drying of wood?

Certain conditions are necessary for effective atmospheric drying of wood. First, ensure good ventilation - there must be enough space between the boards for air circulation. Secondly, consider the humidity and temperature of the environment. Too high a humidity or too low a temperature can slow down the drying process. Thirdly, the wood must be protected from direct precipitation and excessive moisture.

7. How long does it usually take to atmospherically dry wood to a moisture content of approx. 20 %?

The time it takes to atmospherically dry wood depends greatly on the type of wood, its size and environmental conditions. It usually takes from a few weeks to a few months. In some cases, especially for thick hardwood boards, drying can take even more than a year.

8. What problems can occur during atmospheric drying of wood?

Various problems can occur during atmospheric drying of wood. These include: cracks and warping in the wood due to uneven or too rapid drying, the appearance of mold and mildew due to excessive moisture, and loss of wood colour due to direct exposure to sunlight.

Using wood with a moisture content of 20-22%: Overview

What is the moisture content of wood?

The moisture content of wood is a quantitative expression of the amount of water contained in the wood. It is an important parameter which affects many properties of wood, such as strength, density and durability.

The importance of wood moisture

The moisture content of wood plays an important role in its use. When wood dries, it shrinks and can distort, making it less attractive for construction and other applications. On the other hand, if the wood is too damp, it can fall prey to rot and insects.

Moisture content of wood 20-22%

Wood with a moisture content of 20-22% is quite optimal for most applications. This means that there is enough moisture in the wood to prevent dryness and delamination, but not so much that it promotes rotting or attracts pests.

Where is timber with a moisture content of 20-22% used?

Construction and housebuilding. Wood with this moisture content is often used in construction.

Furniture manufacturing

Such wood is also widely used in furniture production, particularly for outdoor furniture. Humidity in this range prevents cracks and bends that can occur with overly dry wood.

Advantages of using wood with a moisture content of 20-22%

Using wood at this moisture level offers many advantages, including improved strength and durability as well as a reduced risk of warping.

In conclusion, timber with a moisture content of 20-22% is an excellent choice for many applications, including construction and furniture manufacture. Its properties provide strength, durability and resistance to distortion, making it the preferred choice for many consumers and manufacturers.

We hope that you have found the overview of atmospheric drying of lumber useful and interesting. We are sure that you now have all the knowledge and skills you need for your timber projects!

If you want to dry boards on your own and you only need to buy sawn timber in Moscow and Moscow region we are always glad to see you in our factory. Our friendly specialists are always ready to help you choose the best product for your needs and answer any questions you might have. Don't hesitate to come and see us, we are always happy to make new acquaintances!

Wood manufacturer & Timber supplier

Timber Expert